Don’t See What You Are Looking For?

Give Us A Call! (757) 548-4842

Monday – Friday 7:30 am – 4:30 pm Eastern Time

Monday – Friday 7:30 am – 4:30 pm Eastern Time

JH Norton Company Inc.

Knowledgeable Staff Since 1973

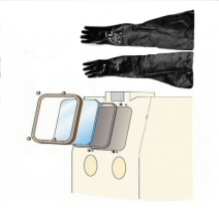

JH Norton Company Inc. supplies many types and sizes of sandblasting equipment, abrasive blasting parts, and accessories. We offer abrasives / blast media, blast rooms, nozzles, couplings, wet blasters, sand blasting cabinets, abrasive blast equipment, and many sizes and types of portable blasters. We supply dust and fume collectors, blast machines, parts washers, sponge blast, dry ice blasters, and baking soda blast cleaning systems. We also offer air-supplied (air-fed) respirator helmets / hoods, hoses, vacuum systems, safety equipment, blast suits, personal protective equipment (PPE), power tools, reclaim systems, parts, accessories and much more. We have what you need for surface preparation! We have your solution for rust, corrosion, coating, and paint removal from small jobs (hand-held wheel/brush belt blaster) to large industrial, shipyard and commercial projects!

We’re leading in automation and robotic technologies for advanced surface preparation. We offer quality commercial sandblasting equipment for sale at affordable prices. We supply industrial blast equipment and replacement parts from blast industry leaders such as RPB® Nova™, Schmidt® Axxiom, Empire®, Clemco®, Eliminizer™ Application Dryer, Eliminex™ Separator/Filter, Baking Soda Blasters Arm, and Hammer®, HoldTight® Wet Blasting, Ecoquip by Graco®, AmphiBlast™, Monti® MBX™ hand held surface prep tools, Sponge-Jet®, Western Technology and Adapt Laser®.

Visit us on Facebook.